Hulas Plain Sheets

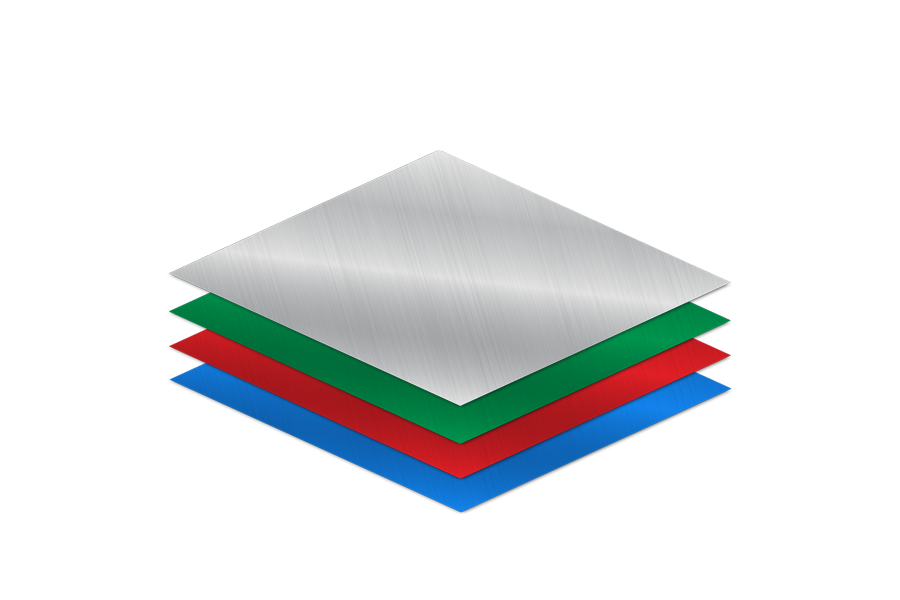

"Hulas DuraColour" is a premium roofing solution. "Galvaalum" coils (Steel coils coated with Al-Zn) are preprinted with Primer on both sides (Top and Bottom). Then applied with Topcoat and Bottomcoat of paint, with a total coating of 35 Microns. The paint used is specifically designed to meet the high standards of UV protection, ensuring high gloss and a long life – DuraColour.

The division started manufacturing color-coated sheets in 1989, long before the concept was even heard of in the entire SAARC region. The plant, using the most sophisticated Japanese technology, uses the term 'Color Coating,' which is also referred to as 'Duplex Coating.' The first coating is the outer coating to provide color (e.g., for appearance or easy visibility) or camouflage, and more importantly, additional corrosion protection. Pre-painted sheets manufactured by Hulas confirm to JIS-G-3312 and IS 14246-1995 standards.

‘GALVAALUM’ Sheets are cold-rolled sheets coated with 55% of Aluminum, 43.5% of zinc, and 1.5% of silicon. ‘Galvaalum’ offers superior corrosion resistance compared to other coating technologies and increases durability and strength by three times compared to galvanized roofing sheets. Galvaalum is also available in color under the brand ‘Hulas DuraColour.’

For the first time in Nepal, the coating is done using Australian technology, which has increased the lifespan of roofing sheets by three times. Hulas Galvaalum and Hulas DuraColour are available in the Nepali market at respective dealers, depots, and branch offices.