Road safety is a rapidly increasing concern in Nepal, whose challenging geography and rapid urbanization provide the setting for varied and often fatal accidents. The contribution of infrastructure towards preventing the same is crucial, as good quality safety equipment can easily avert road fatalities. Hulas Steel, one of the leading steel manufacturers in Nepal, has emerged as a major enabler of safer roads through its value-added and long-lasting road crash barriers. By combining local manufacturing capabilities with international safety standards, Hulas Steel is particularly well-placed to fulfill the nation's special road safety needs.

Challenges to Road Safety in Nepal

Nepal's topography—steep mountainous highways, varied climate, and narrow highways—poses extremely challenging conditions for road safety. These geographical constraints are also exacerbated by increasing vehicular density, particularly in urban areas and intercity highways. Most of the road infrastructure in most parts is aging and lacks proper safety features such as guardrails and signage.

Hulas Steel: Setting Road Safety Trends

Hulas Steel Industries, which is part of the prestigious Golchha Organization, has taken the forefront of Nepal's local steel industry by being the first to manufacture metal crash barriers. With its years of tradition and history of quality excellence, Hulas Steel has been at the pinnacle of the industry in offering creative solutions to deliver safer rides.With its emphasis on customer happiness and continuous improvement driving its aim to deliver reliable, long-lasting, and economical crash barriers, the organization is set to prove that road safety solutions can be at once relevant and compliant to Nepalese as well as international safety standards.

Introduction to Metal Crash Barriers

Metal crash barriers are organized safety systems that are installed along the sides of roads to prevent automobiles from veering off onto unsafe terrain or into other lanes of traffic. Metal crash barriers play a vital role in protecting drivers and passengers by displacing and dampening the impact of crashes. Based on the specific road conditions and safety requirements across the globe, different types of crash barriers are adopted, including W-Beam, Thrie-Beam, cable barriers, and concrete barriers. In Nepal, where several hilly regions and sharp bends on roads are common, metal crash barriers, particularly W-Beam barriers, have proven highly effective. Their deflective control and redirection of vehicles render them ideal for the rugged roads of the country.

The W-Beam Guard Rail: Hulas Steel's Safety Backbone

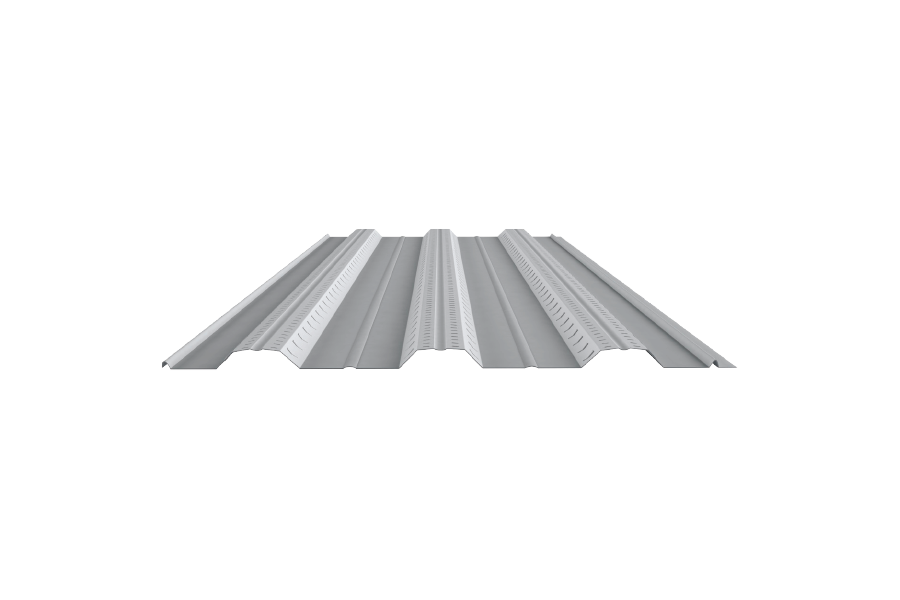

The W-Beam guard rail is the centerpiece of Hulas Steel's range of road safety products. Its "W" shape letter pattern makes it a steel barrier that can absorb the energy from an onrushing vehicle and prevent it from swerving off the road. The ductile yet strong nature of the W-Beam distributes the impact forces of the collision evenly, reducing the effects on vehicle and people. Manufactured under the Nepal Road Standard – NRS 2070 and Indian Standard IRC according to the Ministry of Road, Transport & Highways (MORT&H) specifications, Hulas Steel W-Beam crash barriers are engineered to deliver peak safety performance. The guardrails are apt for highways, bridges, and urban roads, offering protection and durability in high-impact zones.

Components of the Crash Barrier Assembly

Hulas Steel's crash barrier system has three critical elements, each of which plays a critical role in preserving road safety:

W-Beam: This is the longitudinal rail that is centrally designed to deform in case of collision and dissipate collision energy safely.

U-Post: These vertically placed ground-anchored posts serve as the structural backbone of the barrier. They provide anchorage and support to the W-Beam to ensure it remains upright and functional.

Spacer: Spacers are used to produce a predetermined gap between the beam and the post. This gap provides room for flexibility in the barrier and for controlled deformation upon crash incidence. These components as a whole system have strength in withstanding high-impact forces and forms effective roadside protection.

5 Major Benefits Of Using Steel Barriers

Reduced Traffic Jams and Congestion: The crash barriers have a significant influence on decreasing traffic congestion and bottlenecks. Less traffic congestion leads to safer and more efficient driving.

Increased Road Safety: Enhanced highway and road safety resulting in fewer accidents. The crash barriers are useful in preventing an out-of-control car from entering the opposing lanes, therefore avoiding direct collisions.

Low Maintenance:The crash barriers require less maintenance than any other type of road safety barrier. They are tough and can readily sustain severe hits. The crash barrier is designed to last at least 30 years with minimal maintenance.

A substitute to GI Pipe Barriers:W-Beam Metal Crash Barrier is a cheap, fast and appropriate substitute to GI Pipe road Barriers.

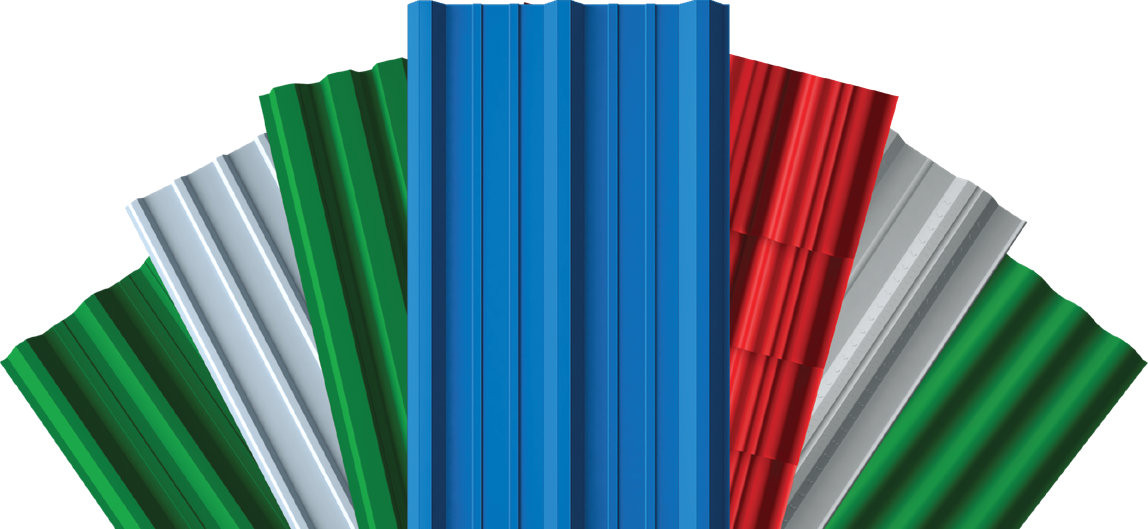

Use of High Technology:The W Beam Crash Barrier is constructed using modern and advanced technology. Thus they can offer the utmost safety on the roads. On the other hand, the metal barriers vary far for many surfaces ranging from coated Zinc. All the materials give excellent service.

Environmental and Economic Impact

As the world today is centered on sustainability, Hulas Steel incorporates environmentally friendly practices into its production process. The company uses recyclable steel, therefore lessening waste and environmental effects for infrastructure developments. Aside from the environmental benefits, Hulas Steel crash barriers also have economic advantages. Through preventing heavy road accidents, the barriers reduce the healthcare service burden, emergency response system burden, and property repair costs. Also, the durability and longevity of the products of Hulas Steel offer government and private infrastructure developers the best value for money, with minimal maintenance needs over time.

Riding Towards Safer Roads

Hulas Steel has revolutionized road safety in Nepal with its high-quality metal crash barriers that are manufactured locally. By adhering to strict national and international standards, the company ensures its products provide maximum protection on Nepal's rugged roads. Hulas Steel's emphasis on innovation, quality, and sustainability has established it as a trusted partner in national development. As Nepal proceeds with the development and expansion of its transport infrastructure, the heavy deployment of Hulas Steel's crash barrier systems will lie at the heart of creating a road network safer and stronger for future generations.

FAQs

Why are Hulas Steel's crash barriers special in Nepal?

Hulas Steel is Nepal's first and only crash barrier producer to satisfy Nepal Road Standards and Indian IRC standards. They manufacture products for Nepal's particular topography with increased performance and strength.

How does W-Beam design enhance road safety?

W-Beam design absorbs collision energy and guides cars back on the road, distributing the force of impact on the people within and preventing vehicles from colliding with hazardous areas.

Are Hulas Steel products suitable for all types of roads?

Yes, the crash barriers are versatile and perfectly suitable for use on highways, city streets, as well as mountain roads. They are engineered to accommodate various types of road conditions without compromising structural reliability.

How long does a metal crash barrier typically last?

With proper installation and regular proper maintenance, the barriers can last more than 20 years, providing long-term protection and good value for money.

How can local municipalities collaborate with Hulas Steel?

Municipalities can collaborate with Hulas Steel via tenders in infrastructure, consulting, and public safety. There is also technical support and installation and maintenance training available from Hulas Steel to ensure optimal safety outcomes

.png)